![]()

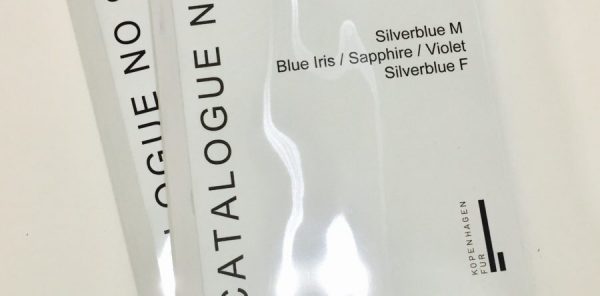

Kopenhagen Fur are the most prestigious producers of mink in Europe and it is a privilege to be selected by Kopenhagen Fur to attend their ‘Fur Sorting & Grading Course’ in Denmark.

The first major element of the course was an illuminating presentation in the auction room on the key statistics and areas of business that makes up Kopenhagen Fur. We covered diverse areas from policy to finance, business structure to global reach, and welfare to traceability.

Our afternoon session ran with a tour of the auction house and warehouse facility with an opportunity to get to know our skins experts who will become our tutors over the next few weeks.

My first impressions:

- The vast size of the cooperative;

- The smell of the undressed pelts!

- The volume of skins and turnover for each auction is vast;

- The cavernous feeling of the place when not full of customers during the auction periods;

- The computerised grading machines can sort Type/Sex/Colour/Clarity/Hair Length. The machines are the future but they have been in development for 15 years and they can’t yet achieve ‘Quality’ assessment. Therefore, the key aspects of ‘quality’ must still be done by an experienced grader.

Farm visit

Day two took us out on the road with a morning visit to the University Research Farm led by Associate Professor Connie Matthiesen of Copenhagen University. This was a very information rich session where we could really get to grips with understanding how scientific farming techniques and excellent animal welfare completely drive the quality of the fur.

The mink farms are light and airy – The mink breeding cycle is driven by day light and ovulation is triggered by the equal length of day and night at the Spring Equinox. Therefore, mink need constant access to fresh air and daylight.

Dressing plant visit

We were very privileged to visit to the last dressing plant in Denmark that specialises in producing some of the world’s best chinchilla skins. The plant is lead and run by Huseyin Karadayi who was very generous with his time and knowledge so we could really get to understand how good dressing is imperative to creating a beautiful, long lasting skin. It was fascinating to see how much traditional, highly skilled craftmanship is still required in this process. One of the key lessons I took away from this session is the importance of keeping the leather supple and ‘alive’ with no fat left on the leather as this can cause stiffness and eventually rotting.

Grading

From day three onwards we hit the grading floor with our practical sessions learning about the different quality factors. The first session was very hard as to the untrained eye it often difficult to see where the cut-offs are between quality levels but, after the second session I felt much more confident with what I was looking ‘and feeling’ for.

We continued with our practical sessions learning to recognise the three main Kopenhagen Fur label qualities: Ivory, Burgundy and Platinum. The fourth category, Purple, is later pulled out of the Platinum label when enough skins represent a ‘premium’ quality.

I really enjoy the challenge of grading – stepping to a new workstation with totally different mink skins makes me excited to see if I can improve my judgements from previous challenges.

Mantra learned from the tutors… “Pick out the best and the worst skin and then… Compare – Compare – Compare!”

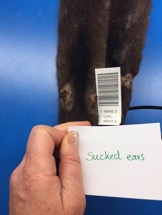

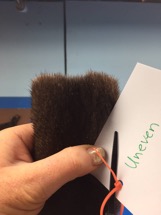

Grading irregular and low-grade skins

Our introduction to ‘irregular skins’ began on day six with learning about listings in the ‘Supplementary Information’ section of the auction catalogue and these must be graded into lots as irregular skins can still be used as they might come out of the dressing process perfectly, so there are potential bargains, but there is a risk.

The ‘low grades/damaged skins’ are worse quality than ‘Irregular skins’. They can still be used for purposes such as trimmings and smaller fur accessories. These skins have a lot of different categories to grade by and the hard part was learning which category ‘trumped’ another for grading purposes as some skins had elements of more than one type of damage.

Grading test

The big individual grading test arrived on day eight! This exam took all morning – we moved through a sequence of test stations where sometimes we were grading overall quality and other just for very specific elements of quality such as ‘surface’ or ‘wool’. We were also working to a time pressure to complete the test. The test was gruelling without the usual support of the tutors to answers our queries as we went along.

I was really pleased with the results of the grading exam – score of 69 and came 4th out of 23. I was happy to note a little bit of ‘girl-power’ as three out of the five girls on the course came in the top four.

After completing our catalogue training and auction practice we all received customer orders from the Commercial Department and we had to use the new auction catalogues for the upcoming June auction and historical pricing from the April auction to prepare a buying strategy, with backup plans. The final auction test came on day 11 with Stig Reinhold, Sales Manager for KF, as the lead auctioneer. It was a real eye-opening process to how the buyers work and how quickly they have to make ‘Plan B’ decisions within the fast pace of the auction.

Graduation

On the morning of day 12 we met Jesper Uggerhøj the CEO of Kopenhagen Fur to receive our Sorting & Grading Diplomas, raise a glass to toast our course tutors and the whole class successfully graduating. Our course leader Sheila Wagner also entertained us with some anecdotes of the course and our fellow students.

Live auction

The 10-day auction with the largest offering of mink to date began on the final Thursday morning with cautious bidding sometimes 9% below the previous auctions sale prices as the skins this time of year are less fresh compared to the December skins that arrive soon after the November pelting.

To conclude…

It has been an honour to be selected for the Kopenhagen Fur Sorting & Grading Course. I have learned so much and made many new friends and work connections who I will cross paths with many times in my career ahead.

The skin knowledge I have gained on the course will positively impact my career as a furrier – influencing my choice of skins, including how and where I buy them and how I market them to my customers. I will also be passing on my knowledge gained to my assistants and interns educating them further about skin types, quality and welfare.

The quality and depth of knowledge offered on the course has been fantastic and a huge ‘thank you’ goes to our esteemed course leader, Sheila Wagner, for donating so much of her extra time, knowledge and resources throughout the course. Our grading tutors, Jan, Eddie, Hannah and Rikke also deserve a special mention for their ‘unending patience’ teaching us the finer details, touch and instinct for grading mink… “Compare – Compare – Compare!”

Read more from: Ninx at Bewitched Couture

A big thank you to Fur Futures and the IFF. I would not have been able to take three weeks away from the design studio to advance my skills in mink fur without the support of the Fur Futures bursary. I will endeavour to pass on the knowledge gained to others that work and train with me at Bewitched Couture. I’m passionate about addressing the skills and age gap in our industry – I will never stop learning:-)!